We choose orbital forming as an assembly process when precision assembly is crucial. Especially if the parts being assembled must pivot about a rivet or type of pin. We can build machines that form rivets that have many types of head forms. We also build machines that can roll over the edge or lip of a tube. Orbital forming is a cold forming process. No external heat source is required. We have the ability to apply a much lower force to the parts during the forming process. We are able to use less force due to the small contact area applied to the part being formed and the use of rotary motion to continuously rotate the tool position while applying a controlled load. We look forward to creating your next automated Orbital forming assembly solution.

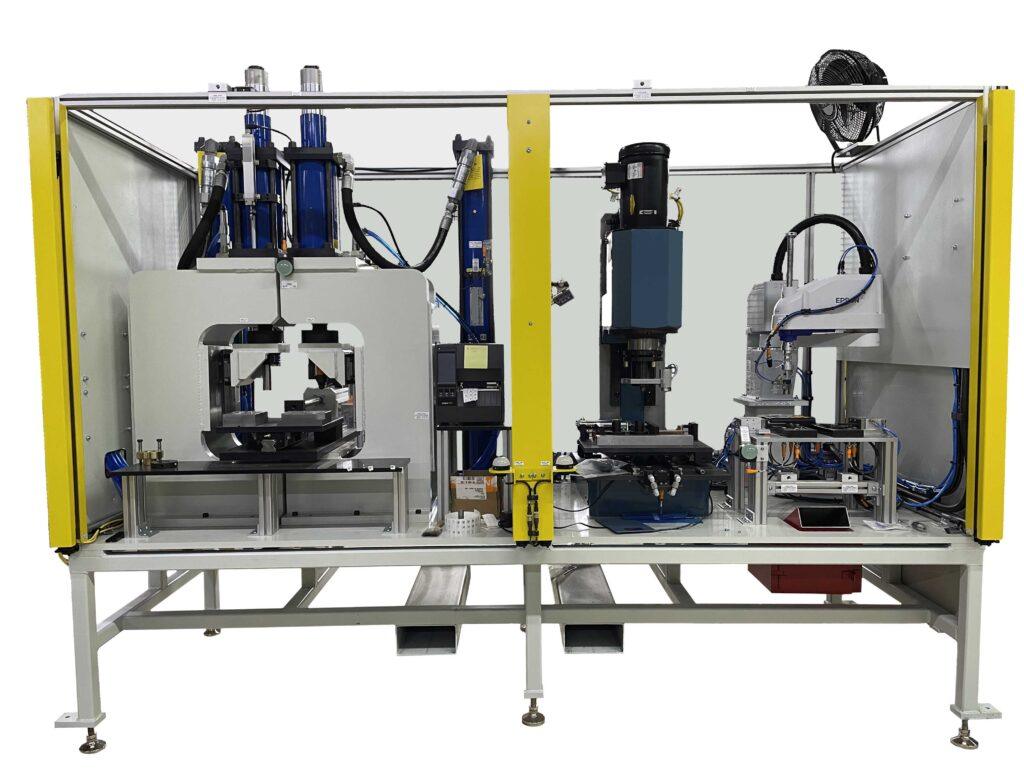

Orbital Flaring Hollow Rivet Mechanism assemblies is a critical process. Many factors drive the required quality requirements while assembling mechanisms. This assembly requires 4 parts to be formed together as a pivoting assembly. We chose the Orbital forming head and tooling very carefully for this process as the mechanisms are critical components relating to functionality and safety.

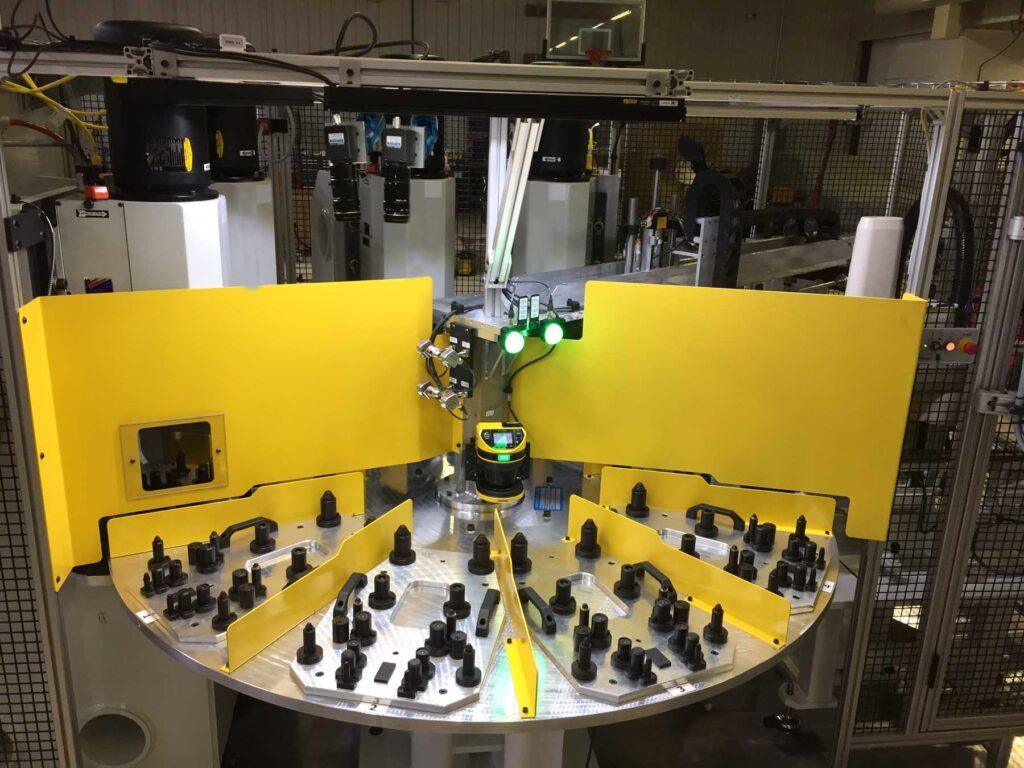

Orbital Forming rivets with this ten-station dial increases production capability and allows the assembly of components to still pivot about the rivet axis as a complete assembly. We Orbital rivet form at four stations and then a final auto unload once the part is complete. We monitor the Force and distance of the forming process. We inspect the rivet form with a camera that has specific parameters in place to assist in determining the quality of the Orbital formed rivet head. Once the part has passed the inspection process it is auto unloaded onto a conveyor.